About US

Innovating Sealing Solutions for Global Industries.

xingda Sealing Parts

Ningbo Xingda Sealing Parts Co., Ltd. specializes in designing and manufacturing high-performance sealing systems for extreme operating conditions. helping clients worldwide achieve leak-free operations and maximize equipment lifespan.

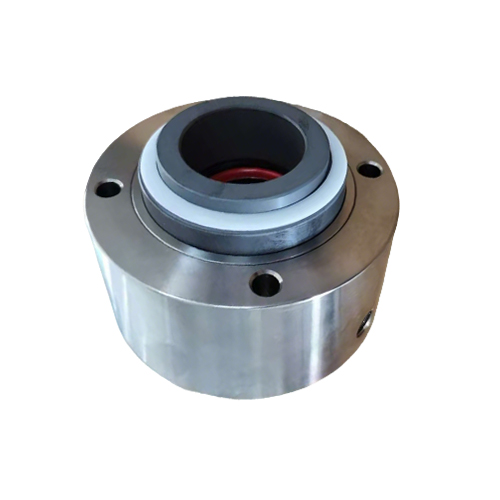

Cutting-edge solutions for high-temperature, high-pressure, and corrosive environments. ISO 9001, API 682, and EN ISO 15848 certified manufacturing with traceable quality control. From standard mechanical seals to customized cartridge seals and IoT-enabled predictive maintenance systems. Our high-performance mechanical seals are engineered to deliver unmatched reliability and durability in demanding industrial applications. Designed for use in pumps, compressors, mixers, and other rotating equipment, these seals ensure leak-free operation even under extreme temperatures, pressures, and corrosive environments.

Crafted from premium-grade materials such as silicon carbide, tungsten carbide, and corrosion-resistant elastomers, our mechanical seals provide exceptional wear resistance and long service life. The advanced hydrodynamic design minimizes friction and heat generation, reducing energy consumption and extending equipment uptime.

Customer repurchase rate

60%+

Ningbo Xingda Sealing Parts Co., Ltd. Let’s seal your success together.

Production advantages of xingda

Interdum et malesuada fames ac ante ipsum primis in faucibus. Duis interdum sem at dictum dapibus. Quisque nec dolor quis lacus pretium vestibulum sit amet et eros. Integer nec arcu vel lectus placerat .

Technology and R&D Advantages

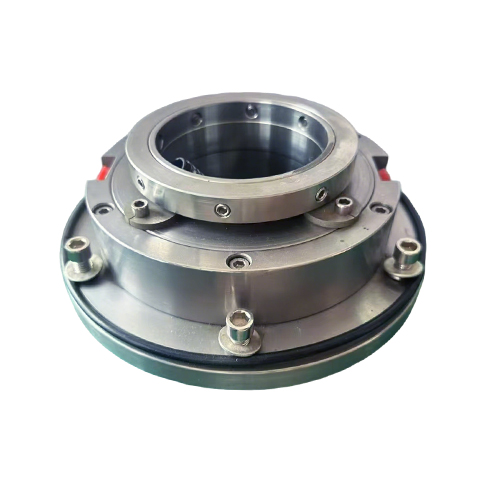

Withstands continuous operation in temperatures from -50°C to 400°C and pressures up to 45MPa.

Rubber seals: High-precision pre-forming machines and vacuum vulcanization technology are used to reduce air bubbles and vulcanization defects; the integrated injection-vulcanization molding process improves production efficiency by over 30%.

Metal seals: Five-axis machining centers are employed to manufacture high-precision sealing surfaces, and laser welding technology ensures that the weld strength exceeds that of the base material.

Composite seals: Multi-material co-injection molding is adopted to avoid secondary assembly errors and enhance sealing reliability.

The characteristics of Xingda Sealing Parts

Crafted from premium-grade materials such as silicon carbide, tungsten carbide, and corrosion-resistant elastomers, our mechanical seals provide exceptional wear resistance and long service life. The advanced hydrodynamic design minimizes friction and heat generation, reducing energy consumption and extending equipment uptime.

- Engineered to withstand high-speed rotation and aggressive media.

- Compatible with a wide range of fluids, including chemicals, oils, and abrasive slurries.

- Precision-machined components ensure seamless integration with existing systems.

- Dual-seal configurations and spring-loaded mechanisms guarantee optimal sealing integrity.

They all chose Xingda

No. 28, Yinfu Road, Danxi Street, Xiangshan County,

Ningbo City, Zhejiang Province