Sealing Parts Experts Around You

—— Ningbo Xingda Sealing Parts Co., Ltd.

Sealing Parts Experts Around You

—— Ningbo Xingda Sealing Parts Co., Ltd.

pressures up to 45MPa

– Withstands continuous operation in temperatures from -50°C to 400°C

Sealing Parts Experts Around You

—— Ningbo Xingda Sealing Parts Co., Ltd.

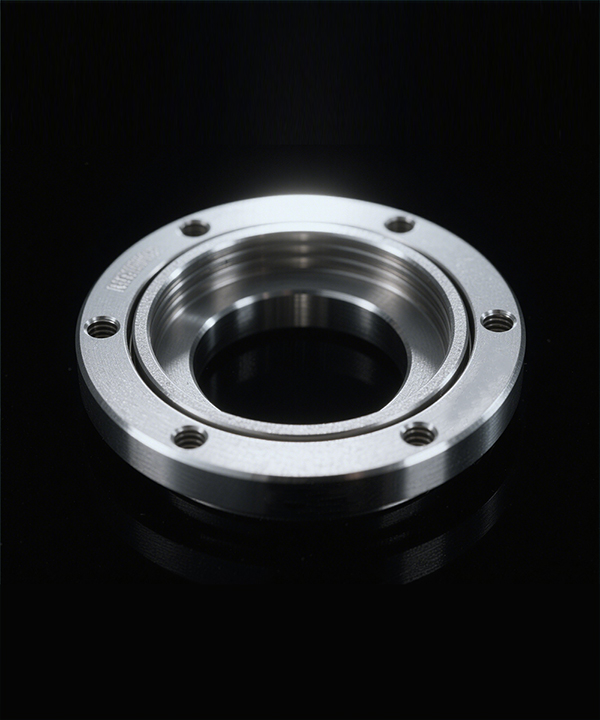

Hot-selling products display

Hot-selling products display

Operating limits

Specification:14~100mm

Pressure:≤1.0Mpa

Temperature:-20℃~200℃

Linear speed:<25m/s

Axial movement: ±0.5mm

Sealing face: Graphite, Silicon carbide, Tungsten carbide, Alumina

Secondary sealing:Acrylonitrile rubber, Fluoroelastomer, Ethylene propylene rubber, PTFE

Metal component: Stainless steel, SUS304, SUS316L

Operating limits

Mediums:water, oil, middle corrosion liquids and other mediumsincludingsolid granule.

Pressure:<3.0MPa

Combination of materials

Rotational speed:<3000r/min

(Linear velocity:<20m/Sec)

Temperature:0°C~+180°C(FPM)

-30°C-+120C(EPR)

-20C~+90C(NBR)

40°C~+230°C(PTFE)

-40°C~+230°C(PTFE cover rubber)

To JB/T 1427-94

Operating limits

Specification:10~110mm

Pressure:<1.2Mpa

Temperature:-20℃~120℃

Linearspeed: <10m/s

Axial movement: ±0.5mm

Combination of materials

Sealing face: Graphite, Silicon carbide,Tungsten carbide, Aluminum oxide

Secondary sealing: Acrylonitrile rubber, Flu-orine rubber, Ethylene propylene rubber

Metal component: Stainless steel

Single seal / Unbalanced / Independent of direction of rotation / Elastomer bellows

Profile

Single seal/Balanced /independent of direc.tion of rotation/Tetrafluoroethylene bellows

This series adopts perfluoroethylene bellows.It is designed with multi-spring structure. Thespring of YYWBz type is protected threugh aperfluoroethylene cover. This mechanical sealis one of the most commonly used seals forcorrosion resistant pumps.

Operating limits

Specification:30~65mm

Pressure:<0.5Mpa

Temperature:-10℃~100℃

Linear speed:<15m/s

Axial movement:±0.5mm

Profile

Medium:Weak acid and weak base liquid.This product is required for cool rinsing with rapid flowing. Select reasonablefrication disc as per work condition, and is to run soundly for long time inS1002858 chemical pump.

Operating limits

Pressure:0~0.8Mpa

Temperature:-20~+150℃

Linear speed:3000r/imin

Profile

Single seal/Unbalanced /independent of direction ofrotation /To DIN 24960*

The M7N mechanical seal range is designed foruniversal application and ideal suited for Standardisa-tion.The loosely inserted seal faces are easilyexchanged, permitting all combinations of materialsand stock rationalisation

Operating limits

d1=14…200mm 0.55”…8”

p1=16(25)bar 230(360)PSI

t=-50…220℃

-58F…430°F

Vg=20m/s 66ft/s

Axial movement:

d1 up to 25 mm: ±1.0mm±

d1 28 to 63 mm: ±1.5mm

d1 65 mm and above: ±2.0mm

Operating limits

Pressure: ≤0.5 MPa

Temperature: <100°C

Linear velocity: ≤10 m/s

Structural Features

PTFE bellows structure compensates for radial shaft movement.

Single-end, externally mounted design for easy installation/removal with visual operation monitoring.

Installation indicator line (center alignment recommended).

Applicable Media

Oil, water, acids, alkalis, organic solvents.

Hydrofluoric acid requires pre-order notification.

Primary Applications

Ideal for acid-resistant pumps and industrial pumps with similar configurations.

Operating limits

PaPressure in the sealed chamber: <1.0MPa

Temperaturein the sealed chamber: -20℃-120℃

Linear velocity:<10m/s

Mediums to be sealed: Clear water, the water with impuri-ties less than 5%, oils and the acid, soda and salt solutions.

The characteristics of Xingda Sealing Parts

The characteristics of Xingda Sealing Parts

Crafted from premium-grade materials such as silicon carbide, tungsten carbide, and corrosion-resistant elastomers, our mechanical seals provide exceptional wear resistance and long service life. The advanced hydrodynamic design minimizes friction and heat generation, reducing energy consumption and extending equipment uptime.

Robust Construction

Versatility

Easy Installation

Leakage Prevention

- Engineered to withstand high-speed rotation and aggressive media.

- Compatible with a wide range of fluids, including chemicals, oils, and abrasive slurries.

- Precision-machined components ensure seamless integration with existing systems.

- Dual-seal configurations and spring-loaded mechanisms guarantee optimal sealing integrity.

Customer repurchase rate

60%+

Ningbo Xingda Sealing Parts Co., Ltd. Let’s seal your success together.

Custom engineering services with 3D modeling and CFD simulation capabilities.

Reduced downtime by up to 40% for clients through precision sealing solutions.

About Xingda

Ningbo Xingda Sealing Parts Co., Ltd.specializes in designing and manufacturing high-performance sealing systems for extreme operating conditions.

ISO 9001, API 682, and EN ISO 15848 certified manufacturing with traceable quality control. From standard mechanical seals to customized cartridge seals and IoT-enabled predictive maintenance systems.helping clients worldwide achieve leak-free operations and maximize equipment lifespan.

Application Areas

our mechanical seals comply with international standards (ISO, API) and are backed by rigorous quality testing. Customizable options, including split seals and cartridge designs, are available to meet specific operational needs.

Sealing reliability in high-pressure, high-temperature and strong corrosion environments to prevent oil and gas leakage from causing safety accidents.

Water-resistant medium is long-term soaked, anti-biological adhesion, and meets hygiene standards (such as drinking water, food-grade water treatment).

Sealing reliability in sterile environments, chemical resistant disinfectant, GMP compliance (no leakage, easy to clean).

Resistant to strong corrosion and permeability, and prevent the leakage of toxic and harmful substances.

What Can Xingda Do

From standard mechanical seals to customized cartridge seals and IoT-enabled predictive maintenance systems.

Reduce Downtime

– Reduced downtime by up to 40% for clients achieved through precision sealing solutions.

Provide Customized Services

– Custom engineering services with 3D modeling and CFD simulation capabilities.

Extreme Condition Reliability

– Withstands continuous operation in temperatures from -50°C to 400°C and pressures up to 45MPa.

Coatings With Acid/Alkali Resistance

– Material options: Silicon Carbide, Tungsten Carbide, or PTFE-coated seals for acid/alkali resistance.

Modular Cartridge Design

– Pre-assembled cartridge seals with ISO 3069 compliance, reducing installation errors by 70%.

Components can be replaced quickly

– Quick-replaceable components cut maintenance time from 8 hours to <1 hour.

Smart Predictive Solutions

-IoT seals with vibration/temperature sensors, offering real-time leakage alerts via cloud platform.

Low failure rate

– Predictive maintenance reduces seal failure rate by 60% compared to traditional models.

What Customers Say

What Customers Say

Message Center

Xingda Practice social responsibility and help the environmental protection industry.

While focusing on its own development, Ningbo Xingda Sealing Parts Co., Ltd. actively fulfills its social responsibilities and has made solid progress in the field of environmental protection. Recently, the

Ningbo Xingda expands overseas markets and signs major international orders.

Ningbo Xingda Seals Co., Ltd. has made significant progress in overseas market expansion and recently signed a seal supply contract worth one million US dollars with an internationally renowned company.

Xingda Sealing Parts Co., Ltd. Tech. Breakthroughs Drive Industry Advance.

(Ningbo, China) In the sealing parts industry, Ningbo Xingda Sealing Parts Co., Ltd. is rewriting the industry structure with a major technological breakthrough. After years of R&D investment and technical